Shop By Category

Related Links

Wire EDM Services: Coquitlam & Vancouver

What is Wire EDM?

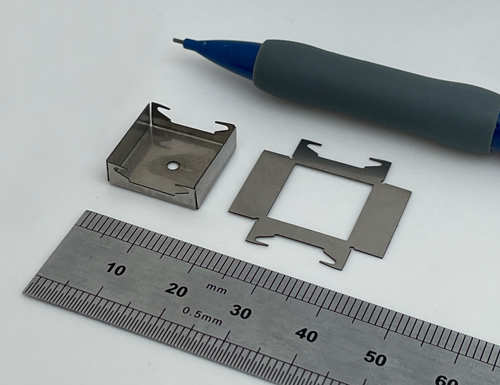

Wire EDM (Electrical Discharge Machining) is a high-precision machining process that utilizes a thin, electrically charged wire to cut through conductive metals. Unlike traditional milling, there is no physical contact between the tool and the workpiece.

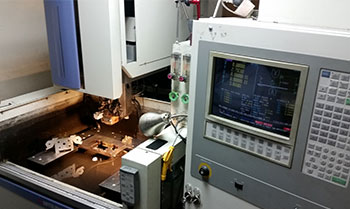

At Punch Tools, our Mitsubishi FX10K machine employs this advanced technology to achieve ultra-fine, intricate cuts. This process is capable of creating precise shapes in hardened materials that are otherwise impossible to machine with traditional drill bits or end mills, resulting in perfectly detailed, burr-free parts.

Precision EDM Setup at our Coquitlam Facility

Precision EDM Setup at our Coquitlam FacilityHow does EDM Wire-Cutting work?

An electrical discharge (spark) is created on a conductive wire (typically brass) that passes through the metal. The entire operation takes place in a submerged tank filled with dielectric fluid.

This fluid acts as a coolant and flushes away the microscopic eroded metal particles. Because the wire is continuously fed from a spool, the "cutting edge" is always new, ensuring perfect accuracy from the start of the cut to the end.

Punch Tools is one of the few facilities offering both Wire EDM and Drill EDM Machining in Vancouver, BC.

Watch: Precision Cutting Tough Metal

What can an EDM Wire-Cutter do?

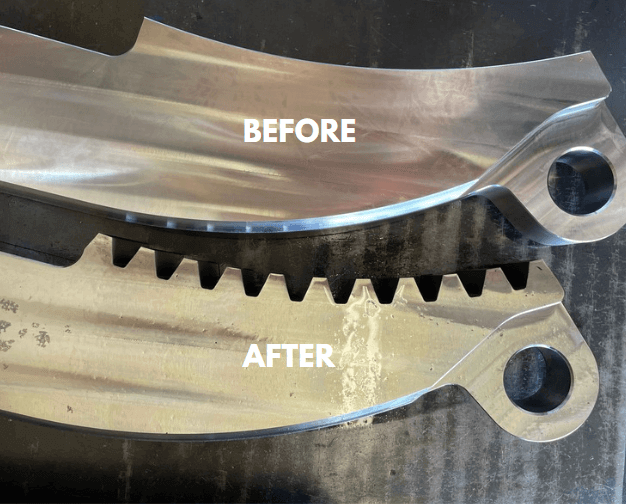

The possibilities are endless. From aerospace components to intricate artistic designs, we extract complex shapes with micron-level precision.

Examples of intricate cuts achieved on the Mitsubishi FX10K.

Why choose Wire EDM?

- No Human Error: Fully CNC controlled for 100% repeatability.

- Handle Hardened Steel: Cut through tool steel after heat treatment to avoid heat-distortion.

- Extreme Tolerances: Achieve accuracy under .001" (one thousandth of an inch).

- Zero Force: Since the wire doesn't touch the metal, thin or fragile parts won't bend during the process.

Ready for a consultation?

Our team is available for projects in Vancouver, Coquitlam, and across the Lower Mainland.

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996